Tomatoes are one of the most popular fruits in the world, and they are used in a wide variety of dishes, from salads and sandwiches to sauces and soups. To ensure that only the highest quality tomatoes are used for processing, they are carefully sorted and inspected before they are processed.

The sorting process of tomatoes in a factory typically involves the following steps:

Washing: The tomatoes are first washed to remove any dirt, debris, or other contaminants. This may be done using a variety of methods, such as water sprays, brushes, or a combination of both.

Grading: Once the tomatoes are clean, they are graded based on their size, color, and ripeness. This may be done manually or using automated machinery.

Inspection: The tomatoes are then inspected for any defects, such as bruises, cuts, or blemishes. Any defective tomatoes are removed from the sorting line.

Sorting: The tomatoes are then sorted into different categories based on their intended use. For example, tomatoes that will be used for fresh packing may be sorted by size, color, and ripeness. Tomatoes that will be used for processing into tomato sauce or other products may be sorted by ripeness only.

Packing: The tomatoes are then packed into boxes or crates for shipment to their final destination.

Manual tomato sorting

In smaller factories, the tomato sorting process may be done manually. This involves workers inspecting the tomatoes and sorting them into different categories based on their size, color, ripeness, and quality. Manual sorting can be time-consuming and labor-intensive, but it allows for a high degree of accuracy.

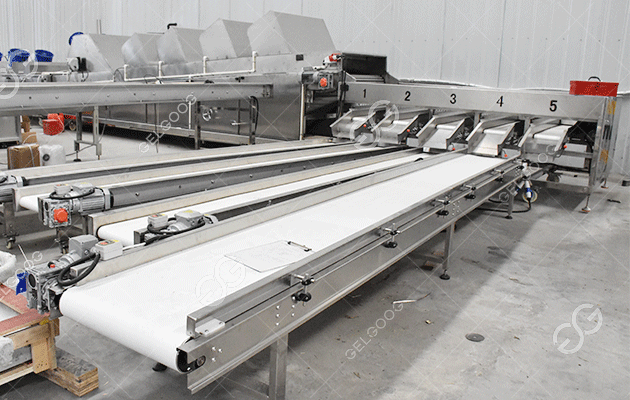

Automated tomato sorting

In larger factories, the tomato sorting process is often automated using specialized machinery. These machines can sort tomatoes based on a variety of criteria, such as size, color, ripeness, defects, and even internal quality characteristics. Automated sorting is much faster and more efficient than manual sorting, but it can be more expensive to set up and maintain.

Benefits of tomato sorting

The tomato sorting process is important for ensuring that only the highest quality tomatoes are used for processing. This helps to ensure that consumers have access to safe, healthy, and delicious tomato products.

Here are some of the benefits of tomato sorting:

Improved quality: Tomato sorting helps to ensure that only the highest quality tomatoes are used for processing. This results in better tasting and more nutritious tomato products.

Reduced waste: Tomato sorting helps to reduce waste by removing defective tomatoes from the processing line. This saves money for food processors and helps to reduce the environmental impact of tomato production.

Increased safety: Tomato sorting helps to improve food safety by removing any tomatoes that may be contaminated with harmful bacteria or other pathogens.

Overall, the tomato sorting line process is an important step in ensuring that consumers have access to safe, healthy, and delicious tomato products.